-

Wear Resistant Steel Plate

-

Stainless Steel Sheet Plate

-

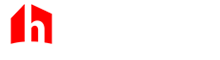

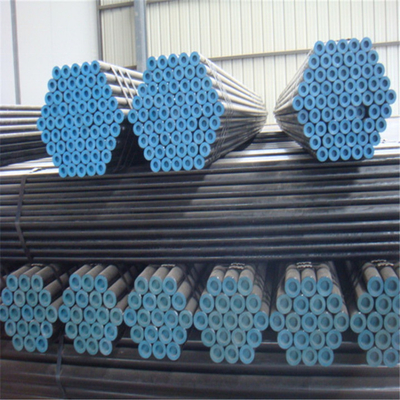

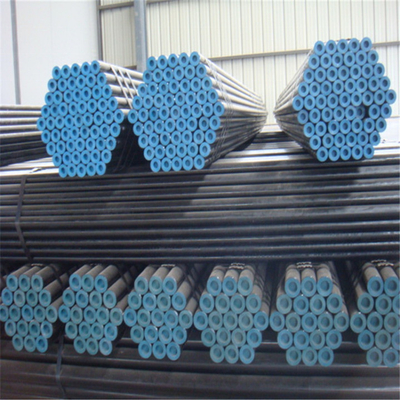

Seamless Stainless Steel Pipe

-

Weather Resistant Steel Plate

-

Shipbuilding Steel Plate

-

Tool Steel Sheet

-

Alloy Steel Plate

-

Boiler Steel Plate

-

Structural Steel Profiles

-

API Line Pipe

-

Colored Stainless Steel Sheets

-

Mold Steel Plate

-

Galvanised Steel Coil

-

Chris ThomasPERFECT!!!!!! high quality, arrived amazingly quick, I am very very happy with this order. Really, the best. thanks!

Chris ThomasPERFECT!!!!!! high quality, arrived amazingly quick, I am very very happy with this order. Really, the best. thanks! -

Alp AydogduSerious and responsible seller, I recommend

Alp AydogduSerious and responsible seller, I recommend -

Yannis Sintosexcellent quality, as described. Great value for money.

Yannis Sintosexcellent quality, as described. Great value for money. -

Philipp EggertProduct compliant and shipped quickly.

Philipp EggertProduct compliant and shipped quickly.

1”To 48”API 5L X65 Seamless Line Pipe 1 - 10mm Thickness

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Seamless Line Pipe | Length | 6m, 12m |

|---|---|---|---|

| Thickness | 1 - 10mm | Steel Grade | Grade B/X42/X52/X60/X70 L245/L290/S320/L360/L390/L415 |

| OD | 1” To 48” | Standards | API, API 5CT, API 5L |

| Highlight | Seamless API 5L X65 Pipe,API 5L X65 Seamless Line Pipe,10mm Thickness Seamless Line Pipe |

||

API 5L X65 Seamless Line Pipe

Description

API 5L Grade X65 PSL1, PSL2, and sour service pipe differences

API 5L X65 PSL1

API 5L Grade X65 or L450 PSL1 pipe is normal carbon steel material among the tree types and for common use, (No corrosion environment but in high-pressure pipelines required certain mechanical properties). so it has the highest content of C, Mn, Si, P, S than the other two types. (These chemical elements is lower the steel is purer). X65 PSL1 pipe Minimum yield strength is 450 Mpa (65300 psi), and minimum tensile strength 535 Mpa (77600 psi).

API 5L X65 PSL2

For API 5L X65 PSL2 (API 5L X65Q.M or L450Q/M), C ≤ 0.18, Si ≤ 0.18, Mn ≤ 1.70, P ≤ 0.025, S ≤ 0.015, all of these elements have less value than PSL1. Since PSL2 requires CEq ≤ 0.43, and CEpcm ≤ 0.25. (Ceq is carbon equivalent, it affects the steel welding performance, and strength value). And because of this, API 5L X65 PSL2 pipe (welded and seamless) mechanical strength has maximum limits: yield strength 450 – 600 Mpa (65300 psi to 87000 psi), tensile strength 535 to 760 Mpa (77600 psi to 110200 psi)

API 5L X65 sour service

API 5L X65 PSL2 sour service pipe (X65QS/MS, L415QS/MS), C maximum is 0.10, Mn ≤ 1.45, Si ≤ 0.45, P ≤ 0.020, S ≤ 0.002, V ≤ 0.10, Nb ≤ 0.08, Ti ≤ 0.06, CEPcm ≤ 0.22. Sour service line pipe requires a strict control on the chemical composition. So to protect pipes from corrosive environments like H2S, low carbon and low CEPcm value will reduce the martensite which is sensitive to the H bubble, so to improve the corrosive resistance to H2S. Moreover, P and S also should be less than normal line pipes. Out of these, the mechanical strength is the same with API 5L X65 PSL2 steel line pipes.

View how chemical composition affects to steel.

According to the data, 74% of pipeline accidents were caused from pipe corrosion, and H2S is the mainly corrosion types in corrosive environments. So it is very important to manufacture steel line pipe for sour service. View API 5L Pipe Specification for more details.

Specification

| Usage | Applicable to the general structure, mechanical structure, water wall panel, economizer, super heater, boiler and heat exchanger with seamless steel tubes, and to transport liquid, gas, oil etc. |

| Process | Hot rolled and cold drawn |

| Type | Double Submerged arc welded |

| Standard | API 5L, API 5CT, ASTM A106/A53, ASTM A519, JIS G 3441, JIS G3444, JIS G3445 DIN 2391, EN10305, EN10210, ASME SA106, SA192, SA210, SA213, SA335, DIN17175, ASTM A179 |

| Certificate | API 5L PSL1 / PSL2, API 5CT |

| Our diameter | 1/8 – 30 inch (10.3-762mm) |

| Wall Thickness | 0.049” – 2.5” (1.24- 63.5mm) |

| Length | Random Length, Fixed Length, SRL, DRL |

| Steel Grade | API 5L: GR B, X42, X46, X56, X60, X65, X70 ASTM A53/A106: GR A, GR B, GR C ASME SA106: GR.A, GR.B, GR.C ASME SA192: SA192 ASME SA209M: T1, T1a ASME SA210: GR.A-1, GR.C ASME SA213: T2, T5, T9, T11, T12, T22 ASME SA335: P2, P5, P9, P11, P12, P22, P91 DIN17175:ST35.8, ST45.8, 15Mo3, 13CrMo44 |

| Surface | Fusion Bond Epoxy Coating,Coal Tar Epoxy,3PE,FBE, Varnish coating,Bitumen coating,Black Oil coating as per customers requirement |

| Treatment |

Heat treatment:Annealed: Bright annealed,Spheroidize annealed, Normalized, Stress relieved, Cold finished, Quenched and Tempered. Mill Test Certificate:EN 10204/3.1B |

The reason why you choose us?

· ISO System

· DNV Audited company

· Industry experience of over 20 years.

· Management Systems-Internal Software

· Monthly Exporting Quantity-More Than 100 Tons.

· Customer location -More than 50 countries worldwide.

· We have the most convenient transport and prompt delivery.

· We offer competitive prices with the best service.

· We have a high technical production line with top-quality products.

· We have won a high reputation based on the best quality products.

![]()

![]()

![]()

Packing & Delivery

![]()

Certificate

FAQ

1. who are we?

We are based in Henan, China, start in 2013, and selling to North America(50.00%). There are a total of about 51-100 people in our office.

2. How can I get your quotation as soon as possible?

Email and fax will be checked within 24 hours, while Skype, WeChat and WhatsApp will be online within 24 hours. Please give us your requirements and order information, and specifications (steel grade, size, quantity, port of destination), we will work out the best price as soon as possible.

3. what can you buy from us?

steel, building materials, iron ore, ferroalloy, Iron ore powder

4. why should you buy from us not from other suppliers?

The company has a large number of spot stock all the year round, and the domestic major steel mills signed a sales agreement, the products have price advantage, fast delivery, sold to each region of the country and even around the world

5. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;