-

Wear Resistant Steel Plate

-

Stainless Steel Sheet Plate

-

Seamless Stainless Steel Pipe

-

Weather Resistant Steel Plate

-

Shipbuilding Steel Plate

-

Tool Steel Sheet

-

Alloy Steel Plate

-

Boiler Steel Plate

-

Structural Steel Profiles

-

API Line Pipe

-

Colored Stainless Steel Sheets

-

Mold Steel Plate

-

Galvanised Steel Coil

-

Chris ThomasPERFECT!!!!!! high quality, arrived amazingly quick, I am very very happy with this order. Really, the best. thanks!

Chris ThomasPERFECT!!!!!! high quality, arrived amazingly quick, I am very very happy with this order. Really, the best. thanks! -

Alp AydogduSerious and responsible seller, I recommend

Alp AydogduSerious and responsible seller, I recommend -

Yannis Sintosexcellent quality, as described. Great value for money.

Yannis Sintosexcellent quality, as described. Great value for money. -

Philipp EggertProduct compliant and shipped quickly.

Philipp EggertProduct compliant and shipped quickly.

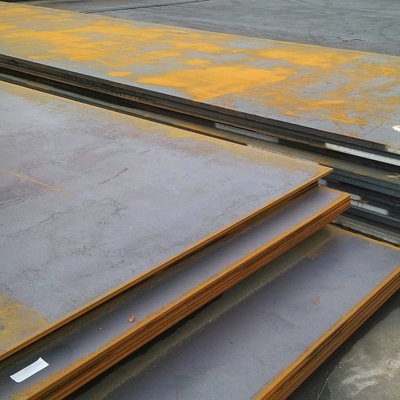

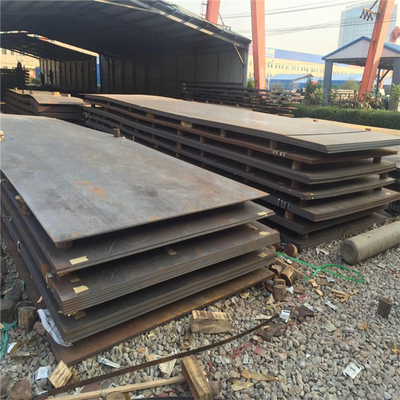

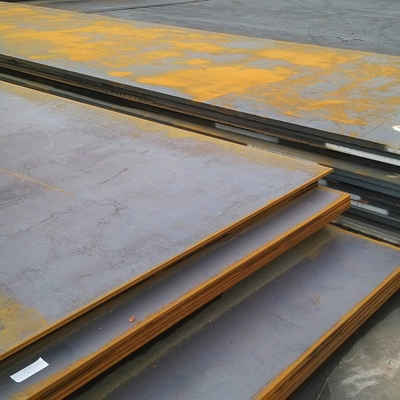

EH32 Shipbuilding Steel Plate 5mm-150mm Thickness 2m 6m Long

| Highlight | Shipbuilding Steel Plate | Processing Service | Cutting |

|---|---|---|---|

| Application | Ship, Container | Thickness | 5 Mm -150 Mm |

| Width | 1500 Mm - 4000 Mm | Length | 2m,6m, 12m, 24m,coils |

| Highlight | EH32 Shipbuilding Steel Plate,Shipbuilding Steel Plate 5mm,Hot Rolled Steel Plate 2m 6m |

||

What is the Shipbuilding Steel Plate?

Shipbuiding Standards from Different Countries

Shipbuilding steel plates are produced according to the classification society,different countries refers to offshore and marine steels in different classification society. Mainly as following:

ABS (American Bureau of Shipping)

BV (Bureau Veritas)

CCS (China Classification Society)

DNV (Det Norske Veritas)

GL (Germanischer Lloyd)

HR (Hellenic Register of Shipping)

KR (Korean Register of Shipping)

LR (Lloyd's Register of Shipping)

NK (Nippon Kaiji Kyokai)

RINA (Registro Italiano Navale)

RS (India Register of Shipping)

What Is Thickness Of Shipbuilding Plate?

The thickness of Shipbuilding Plates ranges between 5 mm to 150 mm. It can be customized according to the specific requirements of the client.

Element |

LR grade A | LR grade B | LR grade D | LR grade E |

| Deoxidation and Thickness (t) in mm | ||||

| t>2.0 in [50mm] | t>2.0 in [50mm] | t>1.0 in [50mm] | ||

| C | 0.21 | 0.21 | 0.21 | 0.18 |

| Mn min | 2.5XC | 0.6 | 0.6 | 0.7 |

| Si | 0.5 | 0.35 | 0.10-0.35 | 0.10-0.35 |

| P | 0.035 | 0.035 | 0.035 | 0.035 |

| S | 0.035 | 0.035 | 0.035 | 0.035 |

| Ni | - | - | - | |

| Cr | - | - | - | - |

| Mo | - | - | - | - |

| Cu | - | - | - | - |

| C+Mn/6 | 0.4 | 0.4 | 0.4 | 0.4 |

Chemical composition of higher-strength LR marine grade steel plates:

Element |

Chemical composition (heat analysis% max) | |

| AH/DH/EH32 AH/DH/EH36 and AH/DH/EH40 |

FH32/36/40 | |

| C | 0.18 | 0.16 |

| Mn | 0.90-1.60 | 0.90-1.60 |

| Si | 0.10-0.50 | 0.10-0.50 |

| P | 0.035 | 0.025 |

| S | 0.035 | 0.025 |

| Al min | 0.015 | 0.015 |

| Cb | 0.02-0.05 | 0.02-0.05 |

| V | 0.05-0.10 | 0.05-0.10 |

| Ti | 0.02 | 0.02 |

| Cu | 0.35 | 0.35 |

| Cr | 0.20 | 0.20 |

| Ni | 0.40 | 0.40 |

| Mo | 0.08 | 0.08 |

| N | - | 0.009 |

Mechanical properties of ordinary-strength and higher-strength LR marine grade steel plates:

Grade |

Tensile Strength ksi [Mpa] | Yield Strength min ksi [Mpa] | Elongation in 8 in [200mm] % | Elongation in 2 in [50mm] min % |

| Ordinary strength | 58-75 [400-520] | 34 [235] | 21 | 24 |

| A B D E | ||||

| Higher strength | ||||

| AH32 DH32 EH32 FH32 | 64-85 [440-590] | 46 [315] | 19 | 22 |

| AH36 DH36 EH36 FH36 | 71-90 [490-620] | 51 [355] | 19 | 22 |

| AH40 DH40 EH40 FH40 | 74-94 [510-650] | 57 [390] | 19 | 22 |

![]()

Chemical and Mechanical Requirements

|

Elements |

C |

Mn |

Al |

Si |

P |

S |

|---|---|---|---|---|---|---|

|

AH32 |

≤0.18 |

0.7~1.60 |

≥0.015 |

0.10~0.50 |

≤0.04 |

≤0.04 |

|

DH32 |

≤0.18 |

0.90~1.60 |

≥0.015 |

0.10~0.50 |

≤0.04 |

≤0.04 |

|

EH32 |

≤0.18 |

0.90~1.60 |

≥0.015 |

0.10~0.50 |

≤0.04 |

≤0.04 |

|

AH36 |

≤0.18 |

0.7~1.60 |

≥0.015 |

0.10~0.50 |

≤0.04 |

≤0.04 |

|

DH36 |

≤0.18 |

0.90~1.60 |

≥0.015 |

0.10~0.50 |

≤0.04 |

≤0.04 |

|

EH36 |

≤0.18 |

0.90~1.60 |

≥0.015 |

0.10~0.50 |

≤0.04 |

≤0.04 |

Shipbuiding Standards from Different Countries

Shipbuilding steel plates are produced under the approval of production methods of classification societies in different countries refers to offshore and marine steels.

- ABS (American Bureau of Shipping)

- BV (Bureau Veritas)

- CCS (China Classification Society)

- DNV (Det Norske Veritas)

- GL (Germanischer Lloyd)

- HR (Hellenic Register of Shipping)

- KR (Korean Register of Shipping)

- LR (Lloyd's Register of Shipping)

- NK (Nippon Kaiji Kyokai)

- RINA (Registro Italiano Navale)

- RS (India Register of Shipping)

|

Mechanical Properties |

|||||||

|---|---|---|---|---|---|---|---|

|

Steel Grade |

Thickness/mm |

Yield point/ MPa |

Tensile strength/ MPa |

Elongation/ % |

V-type impact test |

||

|

Temperature/ ℃ |

Average impact absorption workAkv/J |

||||||

|

Vertical |

Horizontal |

||||||

|

A |

≤50 |

≥235 |

400~490 |

≥22 |

- |

- |

- |

|

B |

≤50 |

≥235 |

400~490 |

≥22 |

0 |

≥27 |

≥20 |

|

D |

≤50 |

≥235 |

400~490 |

≥22 |

-10 |

≥27 |

≥20 |

|

E |

≤50 |

≥235 |

400~490 |

≥22 |

-40 |

≥27 |

≥20 |

|

AH32 |

≤50 |

≥315 |

440~590 |

≥22 |

0 |

≥31 |

≥22 |

|

DH32 |

≤50 |

≥315 |

440~590 |

≥22 |

-20 |

≥31 |

≥22 |

|

EH32 |

≤50 |

≥315 |

440~590 |

≥22 |

-40 |

≥31 |

≥22 |

|

AH36 |

≤50 |

≥355 |

490~620 |

≥22 |

0 |

≥34 |

≥24 |

|

DH36 |

≤50 |

≥355 |

490~620 |

≥22 |

-20 |

≥34 |

≥24 |

|

EH36 |

≤50 |

≥355 |

490~620 |

≥22 |

-40 |

≥34 |

≥24 |

Product Advantages

![]()

PRODUCT APPLICATION

![]()

PRODCTION PROCESS

![]()

Our company offers variety of products which can meet your multifarious demands. We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with anirresistible force.

At present, the company covers an area of 65, 000 square meters, with 9 precision processing production lines, monthly production capacity of more than 500 tons.

Business purpose: Quality first, reputation first, integrity first, recommend all kinds of high-quality products to the society, and serve all industries.

FAQ

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: what is the terms of delivery?

A: EXW, FOB, CIF, CFR, DDU

Q3: What is the terms of packing?

A: generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit. For production period, it usually takes about 15 days-30 days after receiving the deposit.

Q5: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is available in stocks, however, the the transportation fee is borne by buyer.

Q6: How could you guarantee your products?

A: Each piece of products is manufactured by certified workshops. We also could issue the warranty to customer to guarantee the quality.